Greenheck Kitchen Hood Design

After the oil has autoignited it must remain in a pre burn state for 2 minutes with the exception of griddles which remain in a preburn state for 1 minute.

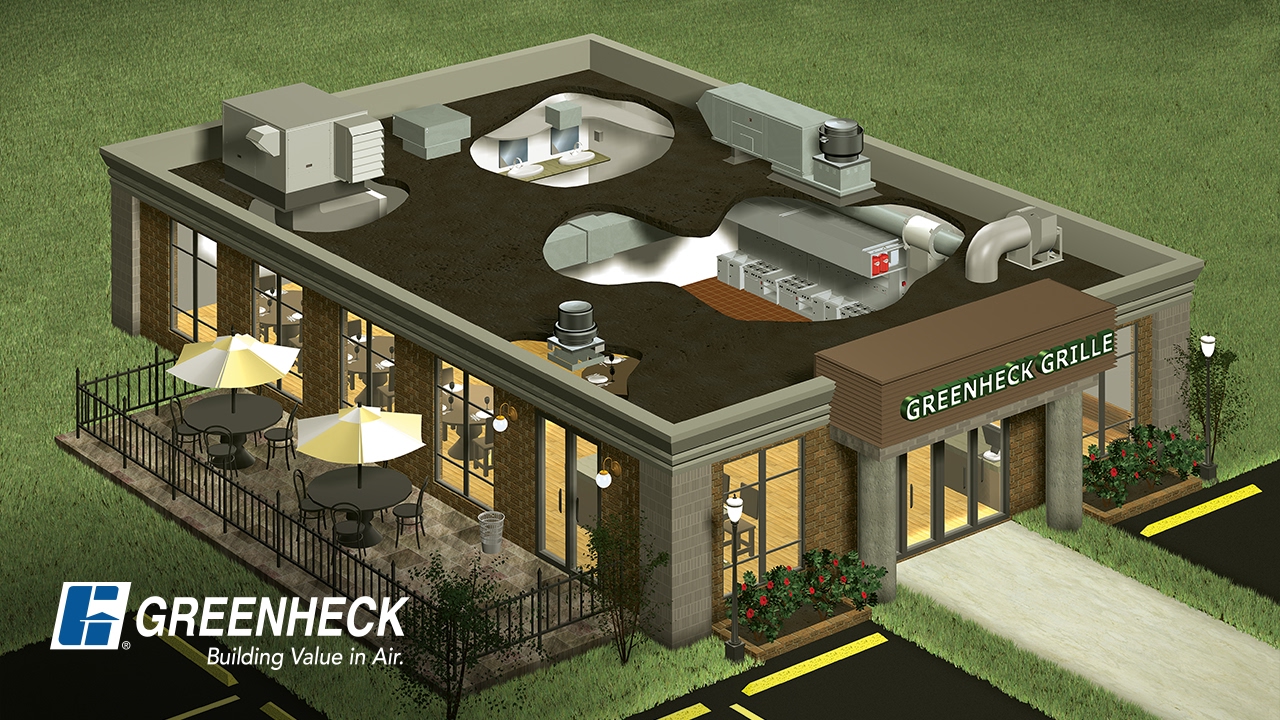

Greenheck kitchen hood design. Our equipment is used across a variety of commercial institutional and industrial buildings in applications. Per 100 feet of duct assuming duct air velocity falls within 1000 1800 feet per minute fittings 008 in. Air duct calculation excel sheets.

Kitchen hoods design and sizing sheets. Not enough supply air brought into the kitchen. Cross drafts in the kitchen.

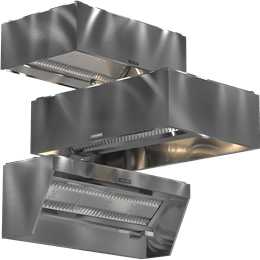

After the hood is installed remove all protective plastic. Kitchen hood is undersized for the application. Ashrae kitchen hood design procedures 2.

Item 1a hood 1b double island. The second sheet contains calculation for wall type and island type kitchen hoods. Learning objectives kitchen design objectives kitchen control technology dcv application and design 2.

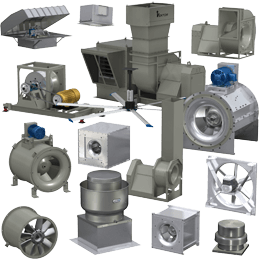

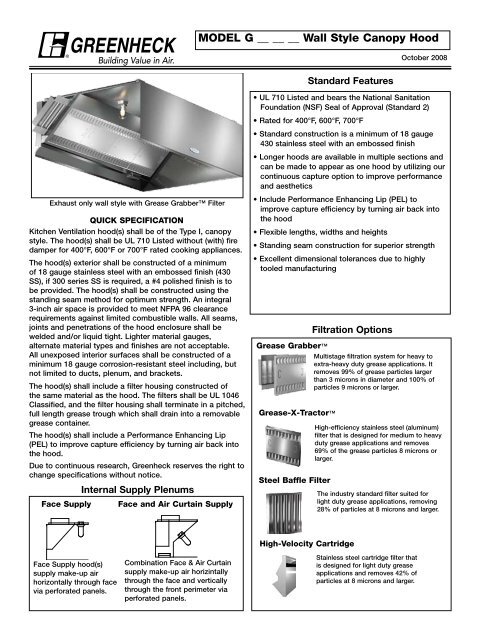

Not enough exhaust air for the cooking load. The breadth of our products and the experience of your local greenheck representative offers you superior and reliable air movement control and conditioning solutions you expect from an industry leader. Since 1975 greenheck has manufactured quality kitchen ventilation components and systems for restaurants and commercial kitchens.

Download design of. In summary ul 300 involves heating vegetable shortening or oil to an auto ignition temperature of 685o f or higher. As the worldwide leader in manufacturing high quality air movement control and conditioning products greenheck offers the most comprehensive line of ventilation equipment available including fans dampers louvers kitchen ventilation systems energy recovery and make up air units.